Cylinder head

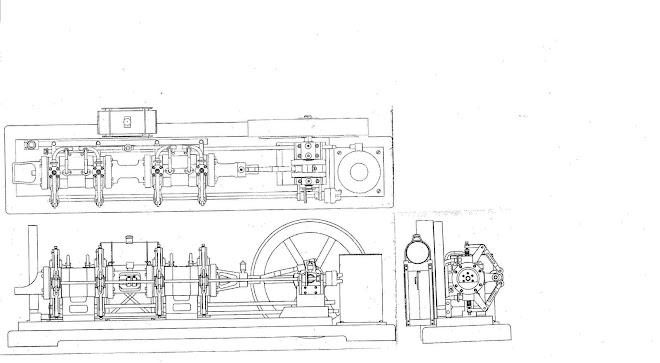

manufacture the cylinder head on the tandem double acting engine

this part was favoriting to manufacture it is cold the cylinder head I cut 4 pieces of 2.50 diameter stock .550 long then I put the part in a lathe and Chuck it in a standard 3 jaw chuck holding no more than .200 once chuck in the lathe I Faced off the part it was good when I Turned the 1.340 diameter .285 deep this diameter is critical it has a -.0005 + .0005 tolerances and it fits into the O.D of the combustion chamber, before Turning the .970 diameter .170 deep I setup a dial indicator on the lathe bed near the spindle then turned the diameter. I chuck a Center drill and the tail stock. look at the print at is time I notice It had a .5625 O.D I thought it would be efficient to drill it to .500 then bore to .5625 I used a bore bar to Chamfer the bore 45 degrees .030 deep and the Chamfer the .970 diameter .060 deep there was a problem when I started to reverse the part at first I woned to chuck the part in a 4 jaw and on the .970 diameter but if I did this it would ruin the finish so I don't ruin the finish on the .970 diameter I Mad some soft jaw and dore the .970 diameter. It use Alot less hassle Turning the 2.150 outer diameter. I Face the back to thickness in the some setup I also Chamfer the bore to 45 degrees .030 deep.

Thursday, January 1, 2009

Subscribe to:

Posts (Atom)